Robotic automation relies on reliable workholding, and these modular pneumatic jaws make it simple.

When automating for lights-out machining, a machine shop must consider everything that could go wrong well ahead of time. During a normal shift, the machine attendant can intervene when necessary, make adjustments to the setup or change out a damaged tool, then start it back up. Without the worker performing in tandem with the machine, it is vital to reduce the chance of error as much as possible. Lathe Chuck Keys

The Schunk Tandem Vise is useful for automating robotic machining cells, including five-axis machining cells. The pneumatic or hydraulic drive enables a high degree of repeatability and consistent clamping force. Photo Credit: Schunk

An important area to consider is workholding, and Schunk VP of sales, toolholding and workholding Michael Gaunce is quite familiar with it. In working with customers, Gaunce has found that flexibility of existing Schunk workholding has meshed well with robotic automation. “When you’re loading a workpiece into the workholding with a robot, speed and simplicity are the biggest factors for success, which is why our Tandem Vise has been so successful,” he says.

The Tandem Vise is a modular workholding system that can be operated either pneumatically or hydraulically using a wedge-hook assembly that increases rigidity. A pair of top jaws connect into the master jaws. The master jaws remain in place at the machine tool — connected to the pneumatic or hydraulic system — while the shop can switch out top jaws for different purposes. The vise comes in different sizes and strokes, with sizes ranging from 64 square mm to 315 square mm and strokes ranging from 2 mm to 15 mm.

When machining unattended, it is vital to reduce the possibility of error. By focusing on simplicity in its programming and drive, the Tandem Vise is well suited to automated applications. Photo Credit: Schunk

The vise operates independently or as part of a bundle that includes all the electrical components and valves needed for installation. To program the vise, the user inputs which valves to open for the jaws to open or close, then repeats that command whenever needed — a process designed to reduce the upfront programming. Gaunce says that the jaws will open the exact amount needed every time, delivering consistent pressure. “The simplicity of the design is really the key here,” he says. “You don’t have to worry about how the grip strength will change because it is a simple open-or-close mechanism.” The bundle also comes with a plug-in that integrates with a robot arm’s control to similarly simplify programming.

Allowing the jaws to only open or close a set amount is mean to reduce the possibility of errors creeping into the system and make it well-suited for automation. “While a ballscrew vise is more flexible,” Gaunce says, “a pneumatic vise has the repeatability of moving the same amount and applying the same force every time.” This repeatability is key to its success with automated cells.

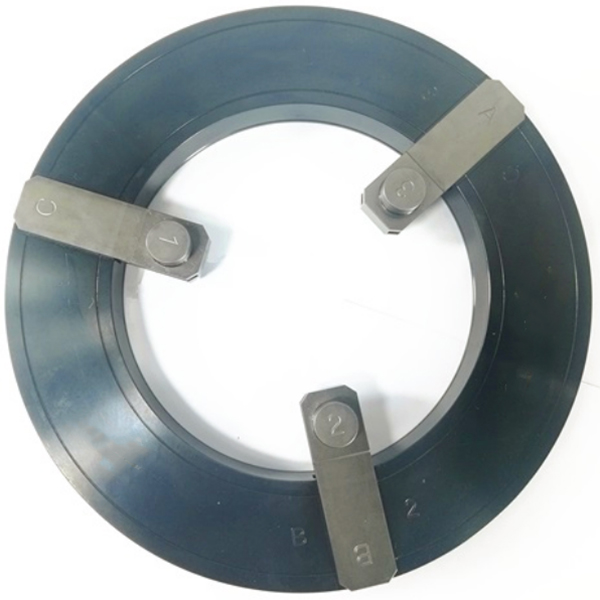

Of course, the Tandem Vise is not just a pneumatic jaw; it’s a modular one, too. The top jaws can be designed to hold oddly shaped parts, or standard flat jaws with or without serrations for extra gripping force. Jaws can slot in at various distances to hold parts of different sizes. The Supporting Jaw series takes this even further and uses attachable inserts that screw onto the top jaws. These inserts include soft, prismatic, pull-down and grip jaws that can be easily switched out.

Read: Schunk Makes a Gripping Debut at IMTS

These inserts attach to the top jaw base, enabling the user to quickly change between a variety jaw types for different applications. This flexibility makes these jaws ideal for automating small-to-medium production runs. Photo Credit: Schunk

The ability to switch out top jaws makes it simple to pivot to another job once a production run is finished. The pneumatic or hydraulic action means that the shop only has to install the proper jaws at the right distance, and it is ready for the part. “We find this vise is especially effective for shops with small-to-medium production runs,” says Gaunce. “The master jaws can remain installed in the machine tool for multiple robot-assisted production runs of 20-300 parts over the course of a month.”

Part of technological progress is finding the ways established technologies and newer technologies mesh together to improve manufacturing. While some of the individual capabilities within this system are not new, it is the benefits that integrated systems can provide to automated machining cells that are becoming more important to today’s job shops.

Finding a way to fixture contoured marine propellors proved to be this shop’s biggest challenge in developing an effective automated machining cell.

Bar pullers are cost-effective alternatives to enable automated turning on CNC lathes. This article explains how they work and how shops can benefit from using them.

Jaw Chuck Turning automation helps this shop produce parts more efficiently.